Improved braking

You've no doubt heard or read about - drilled and slotted brake discs, "performance" pads or reinforced brake hoses. You've seen these terms so many times, you probably don't pay much attention to them. But do you know exactly what these mean in terms of brake performance? There are plenty of misconceptions out there. So get out your notebooks and pens, we're going sort this out once and for all.

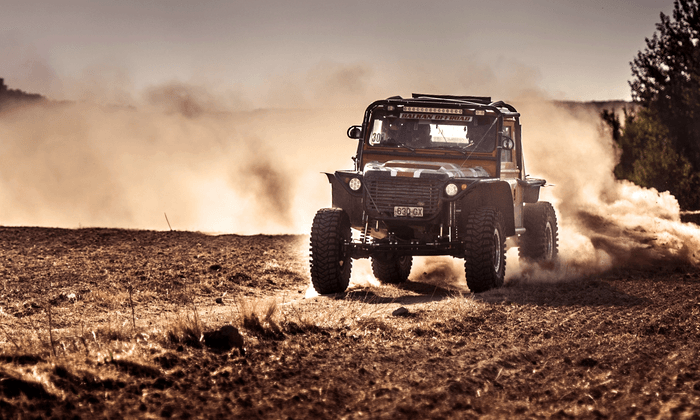

When asked question "what's your idea of a great vehicle preparation?" 75% of enthusiasts reply with "improved engine performance, better suspension , accessories or protection ... In the long list of regular answers, improved brakes comes almost at the bottom of the list. This is surprising, isn't it?

This is even more surprising when you consider that we're normally talking about 4x4 vehicles that weigh in at a minimum of between 2 and 2.5 tons under normal use. And this is probably an underestimation!

Why improve the braking of your vehicle?

Indeed, on a fully expedition prepped 4x4 just imagine those extra kilos. A winch with its mount and there you have an extra 50 kg. An interior set-up, add another 50 to 100 kg depending on the materials used. A water supply of 60 liters means 60 kg more ... At this rate, a HDJ80 or an "Africanized" Defender can see their weight readily increase by half a ton. Same goes for vehicles prepared for off-roading! A metal bumper, large tires, the full range of protection required and you end up with a 4x4 considerably heavier than when it left the factory. Many enthusiasts forget about this extra weight. Another equally important omission: the advent of electronic management means increasing engine power is a veritable breeze. With a power mod box,your 4x4 suddenly boasts an extra 20, 30 or even 50 bhp. Major preparations combine these two scenarios (increased engine power and extra weight up on the scales).

You can now understand why the owners should not hesitate when it comes to optimizing the braking system. How? Let's have a look...

What are the options?

Now let's see how it is possible to improve braking efficiency. Three options are available to you. Unfortunately, two of them are technically difficult to achieve. The first is to simply increase the size of the disk. This is what Japanese engineers did on the HDJ 80 in 1992! Indeed, well before the release of the 24 valve version, the front discs on the Land Cruiser went from 286 mm to 311 mm in diameter. The pads, however, remained the same for both types. At first glance, this size increase might be seen as anecdotal ... except that by moving the point of friction away from the centre of the hub by just a few centimetres, the brake requires less hydraulic pressure for identical performance. So, if you "push" the brake pedal in the same manner on a Series 8 before 1992 and after 1992, your braking distance will actually be reduced with the second. Unfortunately, such a change can only take place before the vehicle is built i.e during the pre-production design phase. Another way to optimize the braking would be to increase the pressure of the pads on the disc. To do this, would means changing the size of the caliper pistons. Once again, only a vehicle manufacturer could achieve this kind of optimization before production. Therefore as an individual you do not really have a choice: the only possible improvement boils down to improving the friction performance of the pads. In other words, fitting so-called "Racing" or "Performance" pads!

Lesson over, now you know what to do!

Slotted discs: the opposite to what we imagine!

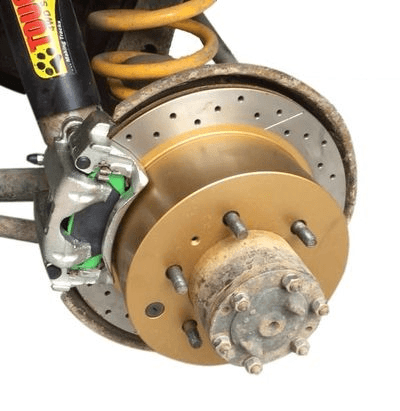

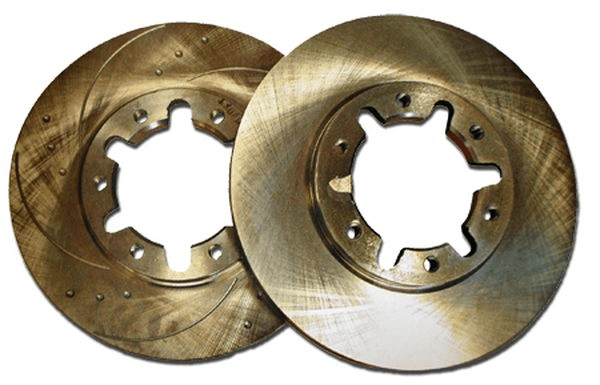

Many enthusiasts believe that slotted disks significantly improve braking. Well, not really! Slots or grooves across the surface of the disk, don't actually contribute to braking efficiency. They actually serve a different purpose. To understand, let's get back to some theory. By rubbing against the disc a pad creates a phenomenon of micro-smoothing on the disc surface (called strain hardening) and causes the metal to heat up. Suddenly, the cast iron is subjected to strong surface stress. Under these conditions, it only takes a tiny outside factor such as the presence of water or a sudden drop in temperature for micro cracks to appear on the on the faces of the disc, or even worse, the disc might warp. Grooves on a disc serve to prevent this kind of deformation. Indeed, because they are placed at regular intervals, the stress created by the friction of the pad is not spread over the entire disk.

In a word, the grooves are simply lines to break the stress exerted on the cast iron. In the same way, holes or punches, added between the grooves of the disc, are also used to reduce the risk of micro cracking and warping. So, in other words, slotted discs are advantageous for the life of the disc and nothing else!

Choose the correct slotted discs for your 4x4:

We hear all kinds of things when it comes to "performance" braking. For example, slotted discs are often said to offer more efficient brake performance. We asked Georges Graciet for hsi expert opinion...

Between you and me, changing disks for a slotted designs offers no substantial improvement in braking. It's not going to stop your vehicle better! Look at the TGV. To stop a train of 380 tons traveling at 350 km/h, engineers rely on solid steel, 800mm diameter discs matched with sintered metal pads. The only case where the groove improves braking is in wet weather. In the rain, sometimes a film of water or a cushion of steam appears on the surface of the disc, which prevents the pads from rubbing against it correctly. As a result, you feel that your vehicle does not brake. If this occurs, the grooves limit this phenomenon because,the pads lose the moisture as they pass over the slots. But, apart from this case, you will not feel any difference between a full and a slotted disk. In addition, in terms of the actual materials used they are both identical. They consist of iron and some additives (chromium, etc ...).

So why fit slotted discs?

When the pads clamp down on the disc, they generate a micro-smoothing effect and surface stress on the cast iron,. All it takes is for the slightest variable to disrupt things (water, temperature change ...) for the metal to suffer micro cracks or, at worst, warping. For the record, you should know that discs operate at very high temperatures - in the region of 300 to 400 degrees and above, and the variation over time is very brief (they go from 0 to 400° in just a few seconds). Slots on discs reduce the stress on the metal, by "breaking the strain". Consequently, the micro cracks remain within acceptable standards, invisible to the naked eye, and the risk of warping decreases considerably. It is for this reason slotted or grooved discs can also be drilled or punched. These breaks in the metal surface reduces the surface stress. So, basically, with a slotted disc, you have less risk of seeing premature deterioration or warping.

So if slotted discs don't improve braking performance themselves what else can we do?

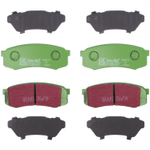

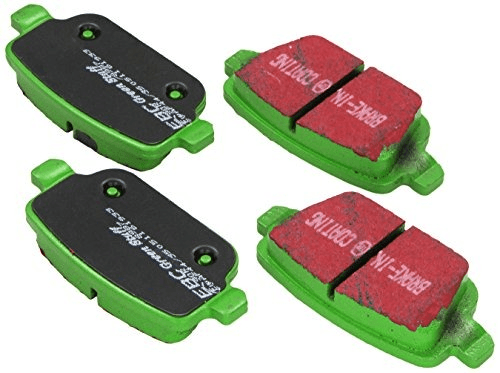

The only technical solution is possible for an individual to opt for more aggressive "racing" or "performance" pads. It's worth knowing that when a 4x4 or any car leaves the factory,they are equipped with pads that have a friction coefficient between 0.36 and 0.42 (A coefficient of 1 would mean that once the pad touches the disc, it would stop dead!). However, brake specialists can make pads more effective by modifying the composition of the linings themselves. This is why so-called "performance" pads can offer a friction coefficient of around 0.47 (and up to 0.60). Thanks to them, without changing anything on the brake system the vehicle will brake better. The downside is that these pads are softer, so they wear out faster. On the GT racing circuit pads are often so soft that they are good for scrap after just one stage.

Performance pads, the only optimization possible

So actually, the only way to really improve the braking of your 4x4 is to change the pads from "genuine quality" parts to "racing" or "performance" pads. The difference between the two resides in the composition of the pad linings, in the mix of aramid fibres/graphite/metal powder used to make them. In the case of the original pads, car manufacturers specify to brake manufacturers that brake pads should have a "normal" friction coefficient without being too harsh on the discs so as not to compromise the discs themselves through premature wear. These pads are often described as hard because their linings erode slowly. Conversely, the "racing" pads offer a higher friction coefficient that results in greater efficiency but the downside is that they "bite" more on the disc. As a result, with this type of pads, the disc will wear faster. The chances are that the disc will quickly become pitted. Another annoyance of high friction coefficients that the "racing" pads wear out faster, too. That is why we often refer to them as "soft" pads. The third disadvantage of these pads is that the disc is put under greater stress. Therefore, if you use "performance" pads on a standard disc (non-grooved), you're more likely to experience warping or micro-cracks appearing on its surface. That is why it is recommended to mount "racing" pads with grooved discs.

Choose the correct slotted discs for your 4x4:

So you just need to change the pads to enjoy more efficient braking?

In theory, yes. But things are not so simple as that, because "performance" pads with their higher friction coefficient exert greater surface stress on the cast iron. So with the slightest incident, the risk of micro-cracking or disk warping is increased. This is why it is better to fit slotted discs at the same time.

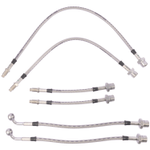

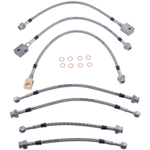

Reinforced hoses

The final improvement that is possible on the brake system: swapping the brake hoses to the reinforced variety, more commonly referred to as "aviation" style hoses. Flexible braided stainless steel covers a synthetic tube as opposed to the standard hose that is made from reinforced rubber tubing. So, compared to a standard hose, "aviation" style hoses don't expand when they are put under pressure. This results in a better response time. But we're talking about tenths of a second. Most people will not even notice the difference. Actually, the real advantage of reinforced hoses comes out when the brakes are applied non-stop. For example, on a small mountain road or overlanding. As these hoses can not expand, the brake remains constant, it does not degrade. Remember the feeling of soft pedal when coming down a hill. With aviation-style hoses, this is less likely to happen. Finally, the ultimate benefit of the hose is that they are made to measure. If your 4x4 has been lifted by 5, 10, 20 or even 50 cm, just specify when ordering and a good supplier will be able to provide you with the exact length required.

Choose the correct reinforced brake hoses for your 4x4:

Reinforced hoses - what's the deal ?

When you press the brake pedal, the hydraulic brake circuit is pressurized. However, with a standard hose, this pressure actually inflates the hose itself, before acting on the pistons. This phenomenon is almost nonexistent in a reinforced hose, thanks to the braided metal exterior. So, you gain just a little improvement in reaction time, but above all, endurance. You no longer experience that "soft pedal" feeling after successive braking! However, as they are more rigid, these hoses can also prove to be more fragile. Generally speaking, they fail at the crimping. Just take a look at the 4x4 carnage during the racing at the Paris 24 hours competition! As they are covered with a braided exterior, they do not break directly, they start to leak. This allows you to continue a little further. In contrast to a traditional rubber hose which, when it breaks, means your journey ends straight away!

Example: Toyota KZJ 70/73

Example: Nissan Patrol Y61

So a final tip for those who want to optimize their the brake performance of their 4x4?

The ideal solution is to change all the pads (front and rear) when the vehicle is equipped with four disc brakes. Some enthusiasts focus above all on the front brakes. I do not recommend it because it completely unbalances the vehicle's braking capacity. Already, the original manufacturers distribute braking on a 70/30 or 60/40 basis, so if you change just the front pads, you might end up with a vehicle brake by almost 80 - 90% on the front axle. This then entails premature wear of the pads and discs. For discs,the ideal solution is once again to change all four to slotted models. However, in practical terms it is perfectly possible to swap just the front discs to slotted and retain the standard "full" discs at the rear.

Article written with help from Matthieu Dadillon

Please note: Euro4x4Parts publishes this information to help its customers but cannot be held responsible for the advice given here and practical consequences that ensue.

We'd love to know what you think!

Whether it’s a mechanical question, a suggestion for an article or a comment on an article you have just read - don't hesitate to send us a message.

Do it yourself, you'll be even prouder! To help you out, Euro4x4parts shares its know-how and expertise in mechanics through 4X4XPERT: new products, technical sheets, and personalized tutorials... You've got the keys!

And because we also learn from your experiences, your feedback is essential. Let us know your thoughts and suggestions by email: 4x4xpert@euro4x4parts.com

Check out our complete catalogue of 4x4 parts and accessories!

All the photos in our articles are taken on authorized roads or tracks, private land, or during supervised competitions. Let's all do our part to preserve the environment!

Please note: Euro4x4parts publishes this information to help its customers, but cannot be held responsible for the advice given here and their consequences when used.