Ignition requirements

There are two types of engines: compression ignition engines (diesel engines) and spark ignition engines (petrol engines, LPG, etc.).

- Compression ignition: the temperature generated by compression is sufficient to trigger the ignition of the mixture.

- Spark-ignition engine: an auxiliary system is required to bring the gaseous mixture to ignition.

Let's look at ignition in petrol and LPG engines first.

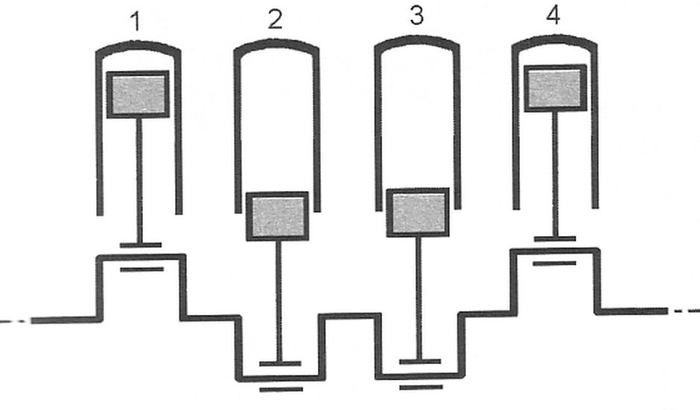

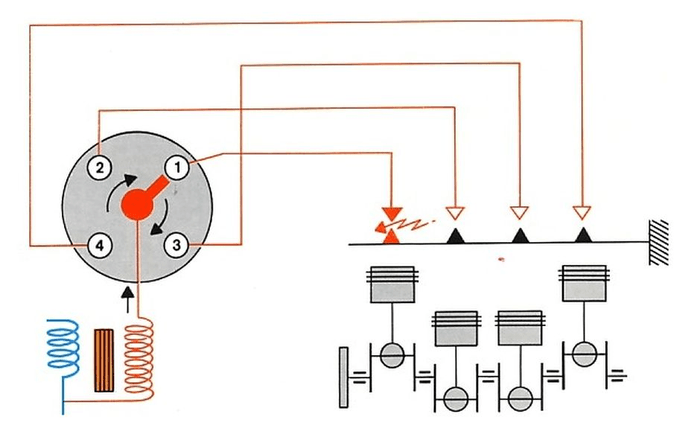

The Firing Order

The firing order is the sequence in which sparks occur in the cylinders.

This order is determined by the four-stroke cycle, it takes into account various parameters:

- The number of cylinders

- The shape of the crankshaft

- The flow rate of gases (intake and exhaust)

- Engine balancing (vibrations, noise)

- Engine performance (efficiency, power, torque)

Cylinder number 1: is on most engines the cylinder located on the distribution side.

The predominant firing order for this type of engine is: 1 - 3 - 4 - 2

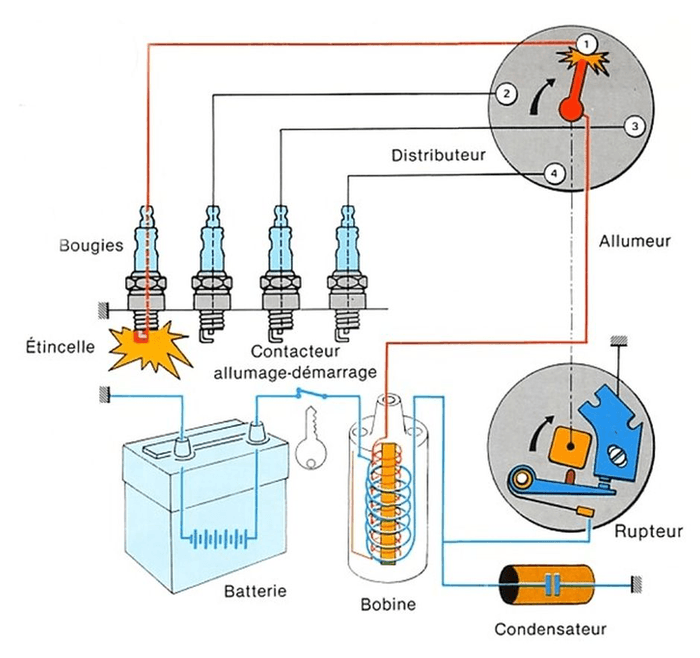

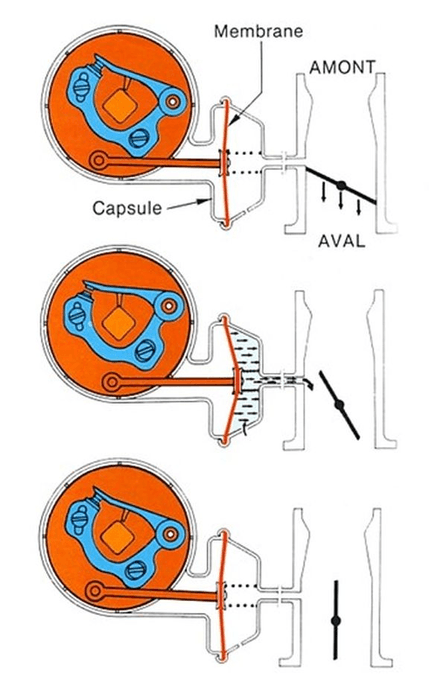

The Ignition System Function

The purpose of ignition is to initiate combustion by providing the heat needed to raise the temperature to the ignition temperature of the mixture.

For this, a brief electric arc, emanating between the electrodes of a spark plug, ignites the portion of the mixture in contact with these electrodes. This initiation of combustion is triggered at a specific moment in the cycle. Combustion continues through auto-ignition across the entire gaseous mass.

Formation of the electric arc

In the open air, the creation of an electric arc between the spark plug electrodes requires a voltage of 2000 volts. In the engine, the voltage must be a minimum of 4000 volts up to 10000 volts.

The voltage depends on the following:

- The pressure in the combustion chamber.

- The richness of the air-fuel mixture.

- The spark plug electrodes.

- The temperature of the combustion chamber and the mixture.

All these factors vary during engine operation. In addition, the circuit is subject to breaks and faults that may occur during operation. The system must supply a voltage of between 12,000 and 20,000 volts to have a safety margin.

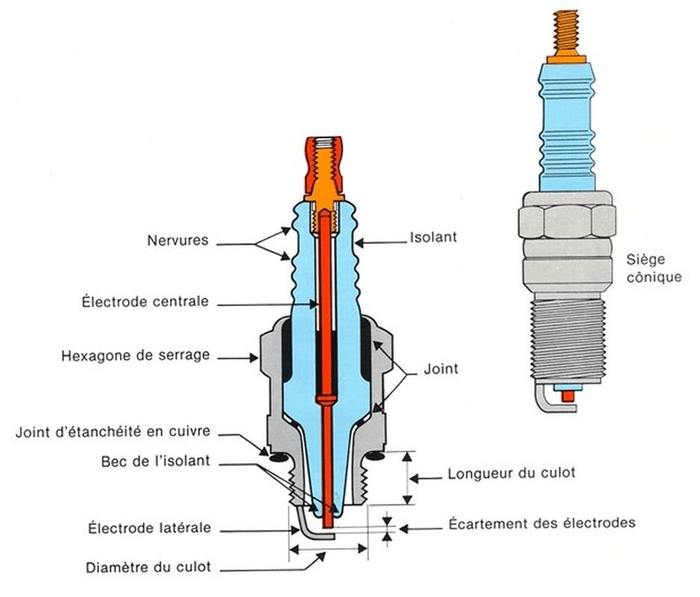

The Spark Plug

When the engine is running at 6000 rpm, 50 sparks per second per cylinder are required, so the choice of spark plug type is crucial.

Spark plugs principal characteristics:

- The heat range, depending on the engine type.

- The type of base, flat or conical seat.

- The number of electrodes.

- Dimensions, diameter, and length of the base.

Voltage Transformation

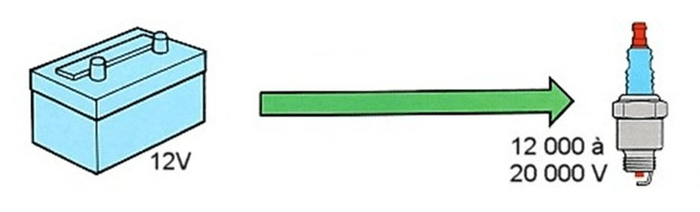

The accumulator battery provides a voltage of about 12 volts. We have just seen that a voltage between 12,000 and 20,000 volts is needed to create an electric arc between the spark plug electrodes.

The battery voltage is therefore transformed into high voltage using a transformer called the ignition coil.

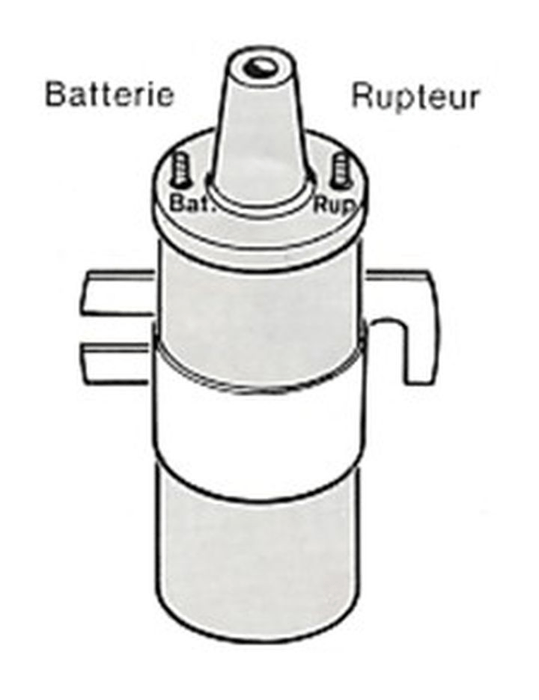

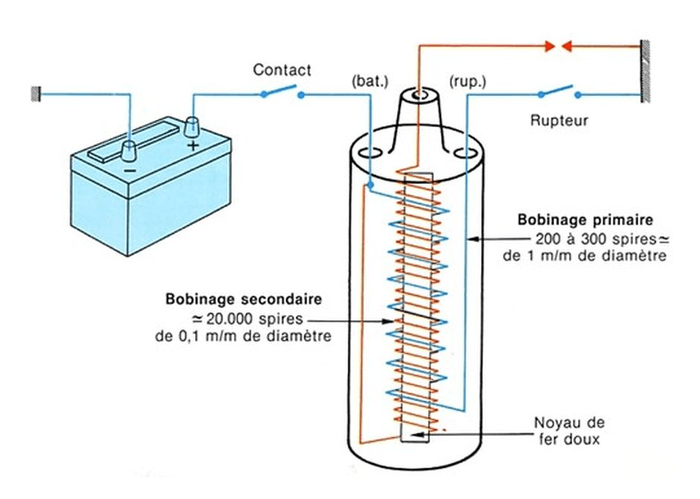

The Ignition Coil

The high-voltage current is obtained by creating an induced current in the coil by varying the magnetic flux.

Each coil is composed of:

- A primary coil

- A secondary coil

- A soft iron core

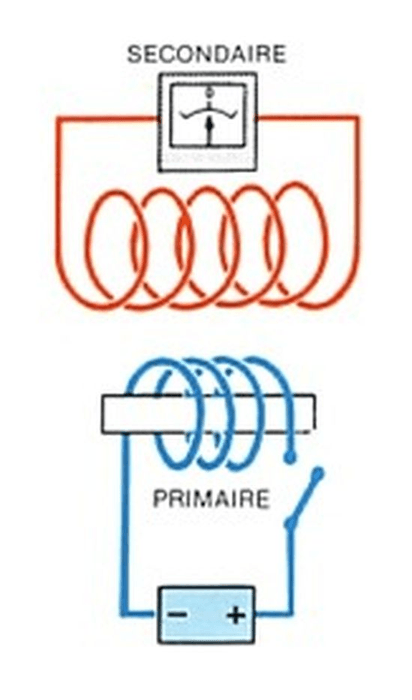

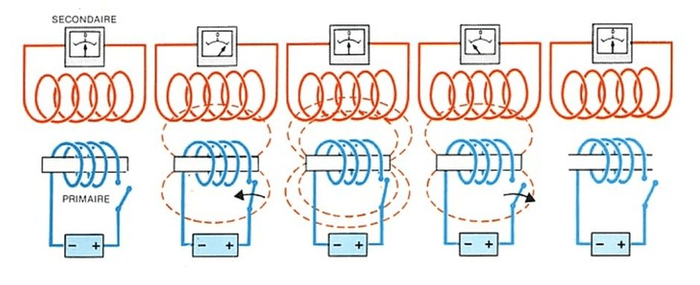

If an electric current is passed through the primary coil, a magnetic field appears around the soft iron core.

When the primary circuit is switched off, the magnetic field disappears.

Magnetic flux is the unit of measurement of the magnetic field; it is expressed in Webers and its symbol is Φ (phi). For a given coil at constant voltage, the value of the magnetic flux is proportional to the current intensity. So, if we vary the current in the primary coil, we will vary the magnetic flux.

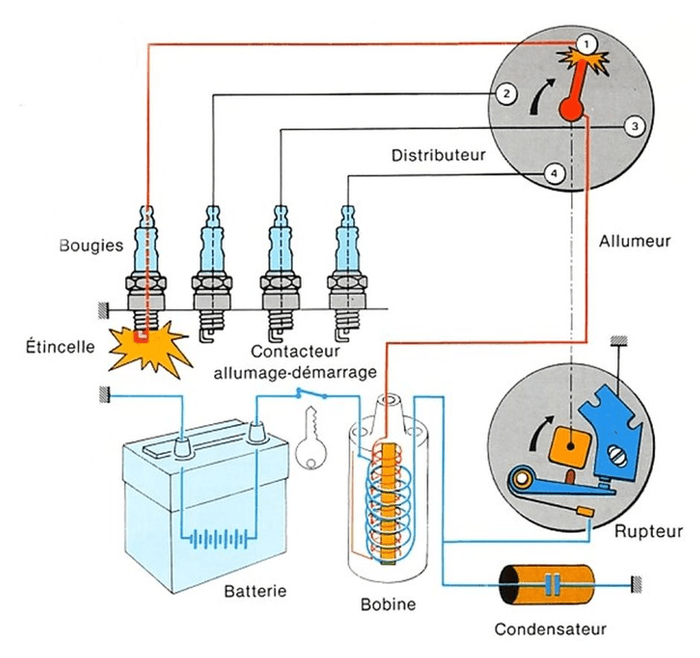

The opening and closing of the primary circuit are performed by a breaker. The breaker is controlled by the distributor's cam.

The secondary coil is also around the soft iron core. With each variation in magnetic flux in the primary coil, there is the creation of an induced electric current in the secondary coil.

Summary:

If we vary the intensity in the primary coil (opening and closing the contact), we will vary the magnetic flux in the primary circuit and thus create an induced current in the secondary circuit.

The secondary voltage is greater when:

- The variation of flux in the core is rapid and significant.

- The ratio between the number of turns of the coil is important.

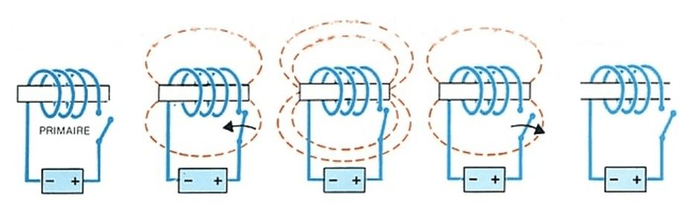

Diagram of how the coil works

Primary current interruption

In theory:

- On closing and opening, the variation should be instantaneous.

- Flux variations should be identical.

- A spark should be produced at the opening and closing of the breaker.

In practice:

- The variation is not instantaneous due to the phenomenon of self-induction.

- When the breaker closes, the variation is long and there is no spark.

- On opening, the variation is rapid and a spark is produced.

The negative effects of auto or self-induction.

When the breaker opens, the self-induction current opposes the circuit's opening and will create a spark at the breaker contacts.

This spark at the breaker has two drawbacks:

- Rapid deterioration of the breaker contacts.

- The circuit's rupture is slow, so the secondary voltage is low, and the spark is also weak.

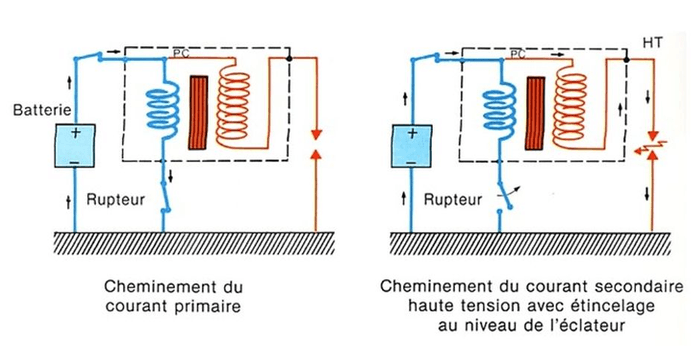

To avoid these drawbacks, a capacitor is used.

The capacitor has two roles:

- Protect the breaker contacts at their opening by absorbing the self-induction current.

- Accelerate the variation and therefore reduce the time, which reinforces the high voltage and thereby the spark.

The capacitor charges when the breaker opens, and it discharges immediately into the primary current. By induction, this phenomenon reinforces the primary voltage, and the secondary voltage is therefore higher.

The Contact Breaker (or Points)

The breaker arm has as many cams as cylinders. The breaker arm is generally driven by the camshaft.

Cam Angle: this is the angle during which the breaker contacts are closed.

Distribution of High Voltage

Sparks must now be distributed to the cylinders, taking into account:

- The position of the crankshaft.

- The opening of the breaker.

- The firing order.

This is the role of the distributor.

The Distributor

This element is a set consisting of the previously mentioned parts:

- The distributor

- The breaker

- The capacitor

The Ignition Point

The ignition point must be precise to obtain the maximum pressure on the piston.

Initial timing: This timing is defined by the manufacturer, and it is valid for the idle speed.

Timing advance mechanism: Engine speed can vary for the same throttle (accelerator) position. Engine fill varies according to accelerator position.

The ignition point must be modified according to:

- Engine speed: centrifugal advance timing.

- Cylinder filling: vacuum advance correction.

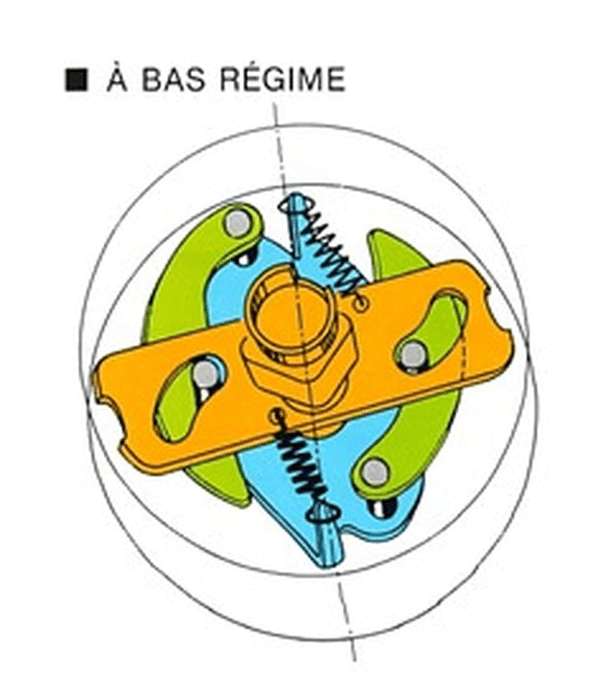

The centrifugal corrector

The adjustment of the timing advance based on the engine's rotation speed is achieved by shifting the camshaft relative to the control shaft. This shift is due to the movement of the weights subjected to centrifugal force, which varies depending on the rotation speed.

The vacuum advance corrector

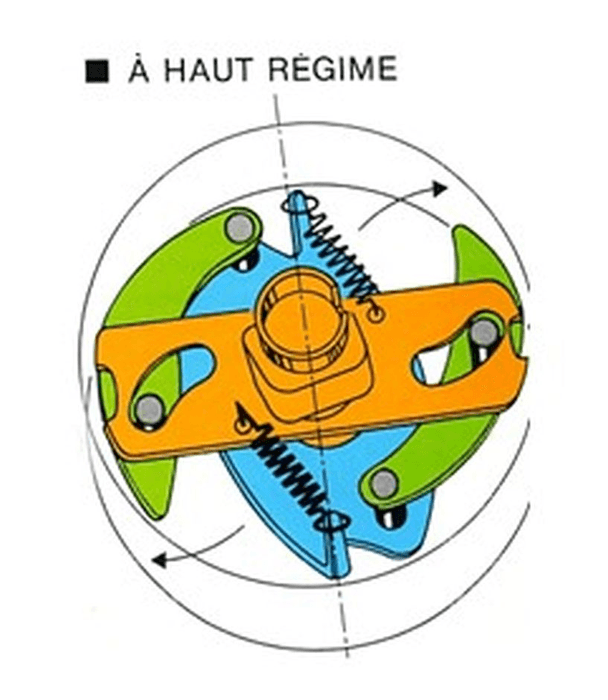

The adjustment of the ignition timing based on the engine's load or vacuum is achieved through a capsule, the position of its membrane changes with the levels of the vacuum.

The movement of the membrane causes an angular shift in the breaker plate, thus altering the timing of the breaker contacts' opening.

Top Image: Idle

The vacuum does not affect the membrane, there's no advance correction.

Middle Image: During slight throttle opening

Vacuum on the membrane is significant. The plate is shifted, and the advance correction is substantial.

Bottom Image: Full-throttle

The membrane is no longer subjected to vacuum, there is no advance correction.

Summary

| Breaker open | Breaker closed |

|

|

1- When the breaker opens:

- Sudden change in flow in the primary circuit.

- The capacitor charges and discharges immediately.

- A high-voltage current is generated in the secondary circuit.

2- The distribution of the high voltage to the spark plug is affected.

3- Spark at the spark plug.

Find the ignition components to suit your vehicle:

Do it yourself, you'll be even prouder! To help you out, Euro4x4parts shares its know-how and expertise in mechanics through 4X4XPERT: new products, technical sheets, and personalized tutorials... You've got the keys!

And because we also learn from your experiences, your feedback is essential. Let us know your thoughts and suggestions by email: 4x4xpert@euro4x4parts.com

Check out our complete catalogue of 4x4 parts and accessories!

All the photos in our articles are taken on authorized roads or tracks, private land, or during supervised competitions. Let's all do our part to preserve the environment!

Please note: Euro4x4parts publishes this information to help its customers, but cannot be held responsible for the advice given here and their consequences when used.